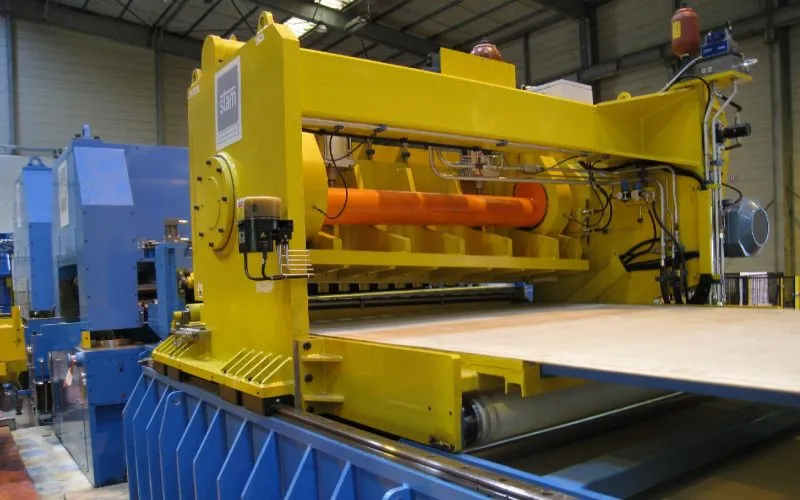

Cut-to-length lines

We supply levelling lines and cut-to-length lines with levellers and lines with rotary and flying shears

We design levelling lines and cut-to-length lines that satisfy the needs of different types of customers:

- High performance lines with great flexibility for coils up to 45 tonnes and work speed up to 120 m/min, suitable for steel mills, service centres, the automotive sector and others.

- Compact and simpler lines, very flexible, in cases where a lower production capacity is required.

Our cut-to-length lines are suitable for processing sheet metal with widths up to 2200 mm and gauge varying from 0.2 to 25 mm.

Our cut-to-length lines can process different materials, such as:

- cold or hot rolled steel

- aluminium

- galvanised steel, pre-painted

- copper

- high strength steel

- zinc

- stainless steel

- alloys

The lines have different configurations, according to the type of material to be processed and the performance required:

- start-stop cutting lines, with roller feeder

- continuous cutting lines with flying shears

- continuous cutting lines with rotary shears

All cut-to-length lines are equipped with software developed in our technical department. They can be customised and interfaced with the customer’s management programs and allow for remote assistance.

Some machines can also be supplied as single unites and can be integrated into existing lines: decoilers, levelling machines, trimming machines with scrap-choppers, scrap winder or scrap wrapping machines, cutting shears, rotary shears, flying shears, stackers and packing lines.

Our 6HI, 5HI or 4HI levelling machines, with interchangeable levelling cassettes, are controlled by a dedicated PC, which manages and saves the settings of the counter rollers and tilting.