Purlin roll forming machines and lines

Purlin roll forming machines are used in the field of building construction for industrial purposes and prefabricated constructions in general

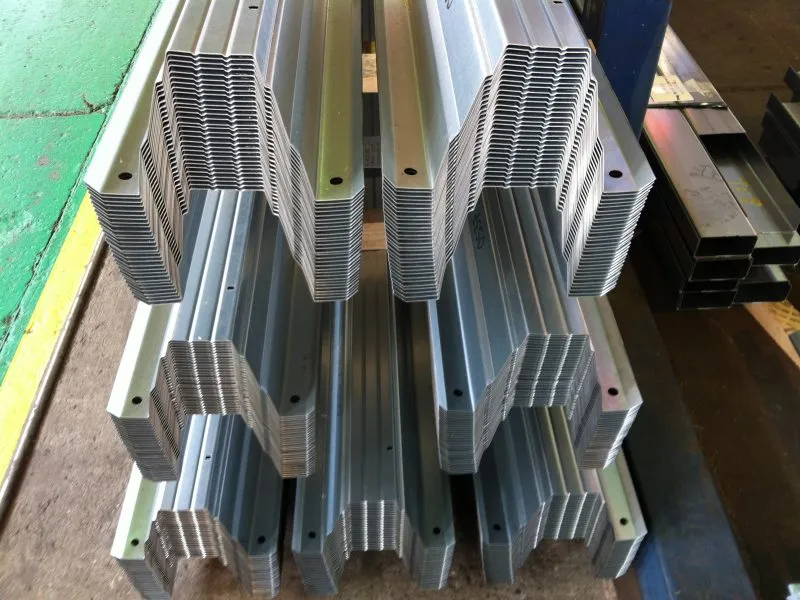

The profiles can have variable sizes, holes and thicknesses. The profile width varies from 100 to 400 (700) mm, the heights from 40 to 100 (150) mm, the thicknesses from 1 to 4 (5) mm, with possible extensions of these ranges. The profiles come with the following section options, C-profiles, U-profiles, Z-profiles and Sigma or Zigma profiles, with the Plus version.

We have developed a more flexible line, compared to the traditional one, to allow for a quick configuration changeover when production changes, in a fully automatic way.

Our purlin roll forming machine is designed in such a way that it is possible to change the profile without changing the forming rolls. Via a system patented by STAM, our flexible roll forming technology, the production changes from C to Z and vice versa in a very short space of time. The machine setting from one profile to the next always takes less than 6 minutes.

A flexible numerical control punching unit makes different holes according to the positions programmed via the computer. This means that the holes are carried out with maximum flexibility, both in terms of the type of hole and its position, either longitudinally or crosswise.

For our most demanding customers we can integrate shaping and laser cutting systems to provide full production flexibility.

The production of C, Z, Sigma profiles can also be made with more traditional roll forming machines, where either the rolls are replaced or they are displaced with a cassette/raft changeover system or telescopic shafts.

Our roll forming lines for purlins can be integrated with an automatic stacking and packing systems.