Lines for variable section profiles

Variable section rollforming or 3D rollforming is an innovation challenge we took up over the last few years

The profiles with variable section are mainly used in the automotive sector. The design of several vehicle chassis and body components require variable sections to meet structural or aesthetic requirements.

Some of them are the profiles used in the chassis of industrial vehicles, both light and heavy trucks, and can be U, C, L or Z section profiles that differ in width in the initial, central and final part.

Traditionally, most of these products are manufactured by resorting to pressing processes, mainly in a press. This involves a large amount of processes, waste of material, expensive tools, low productivity and little flexibility. The pressing process has been taken over by the variable section rollforming.

In 2008, we started designing and building the first variable section rollforming lines for light trucks.

In 2013, we made the first lines able to carry out rollforming on thick variable section profiles used for heavy trucks.

Afterwards, we introduced this technology in the building sector, for light aluminium profiles, including roll-bending processes with a variable radius.

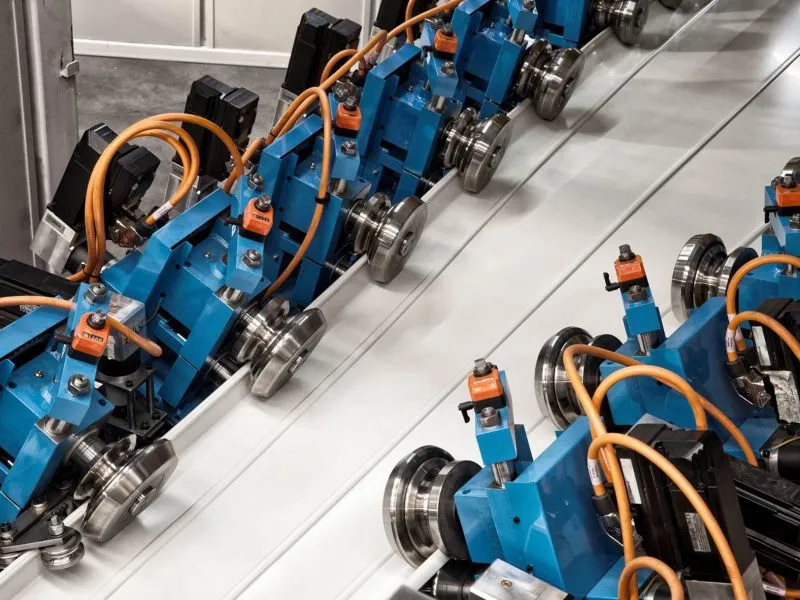

Stam 3D rollformers are equipped with rolls mounted on special stands that move independently. Each stand has its drive motor for roll traction and numerical control servo motors for dynamic positioning. In this way a wide range of workpieces can be manufactured using the same set of rolls.

This layout allows for endless configurations and therefore, with a single series of rolls, we can create the whole range of different pieces.

The possibility of producing variable section profiles with automatic rollforming lines provides enormous advantages in terms of flexibility, lower production costs and the quality of the finished product.