Flexible roll forming

Automatic profile change in just a few minutes

The need for quick production change is progressively more frequent.

The request for production batches that are increasingly smaller, with ever-broader product families, requires the use of suitable equipment and machinery, with high technological content and highly automated.

We propose solutions such as:

- double or twin shoulder machines: automatic movement of rollers, installed on two separate sections, to vary the shape of a profile in height, width and thickness

- revolver machine: the rotation of one or both sections of the roll former, each bearing multiple series of cantilever shafts

- roll former with side-by-side and transversely mobile structures

Some examples:

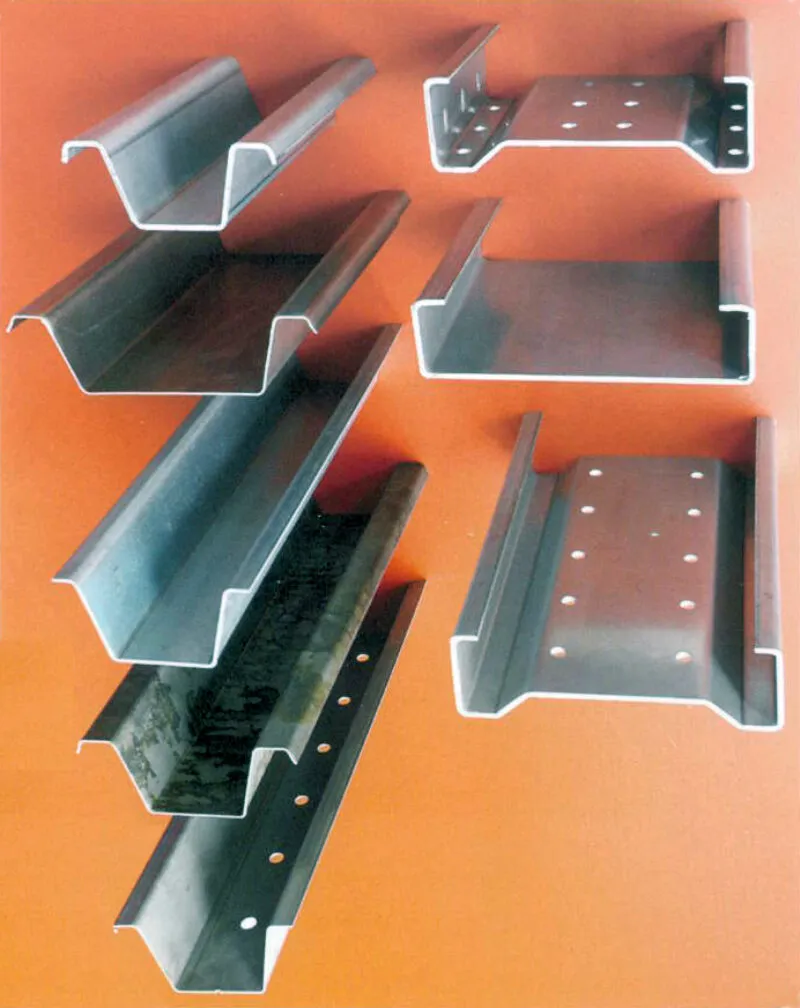

- purlins

- cross profiles in shelving and racking systems

- panels, shelves, uprights

- electrical conduits

- profiles for doors

- beams for heavy and light lorries

- sandwich panels

- half-shells for cold rooms

- trapezoidal, corrugated and deck profiles

A numerical control system that allows you to control the many dynamic axes of the flexible roll formering machines and the operator can program the machine, within the dimensional limits posed by the mechanical part.

Depending on the requirements, we also provide the technologies upstream and downstream of the rollforming process, for example:

- decoiling and straightening

- head and tail welding

- coil perforation

- in-line welding

- cut-to-length

- in-line calendering

- stacking and packing systems